We currently have COP26 in progress:

It is interesting to see activity in the world of shipping seeking ways in which to reduce its contribution to greenhouse gasses. One significant area of interest is the harnessing of wind. This is not surprising, when we consider not too many years ago wind propulsion of ships was the norm. A company I worked with for over twenty years Andrew Weir & Co. Ltd., started its impressive shipping business with the purchase in December 1885 of a second-hand sailing ship the “Willowbank”, it went on to expand its sailing ship fleet to become the largest fleet sailing under the Red Ensign. Of course, Andrew Weir subsequently replaced these with modern steamships and then these, with a modern fleet of motor ships. An excellent book telling the story of Andrew Weir and his company is the book written by a friend and former colleague Captain Alistair Macnab under the title “The Shipping Wizard of Kirkcaldy –Andrew Weir’s Bank Line”. A good read. However, getting back to sail; a number of companies are presently engaged in the design and building of cargo ships using the power of the wind, of course, they will utilize modern materials and up-to-the minute technology.

Jorne Langelaan, who lives in Holland, is a modern day sailor Founder & CEO EcoClipper – Co-founder Fairtransport. He and two of his friends the “Tres Hombres” started the company and named their first Brigantine aptly “Tres Hombres”

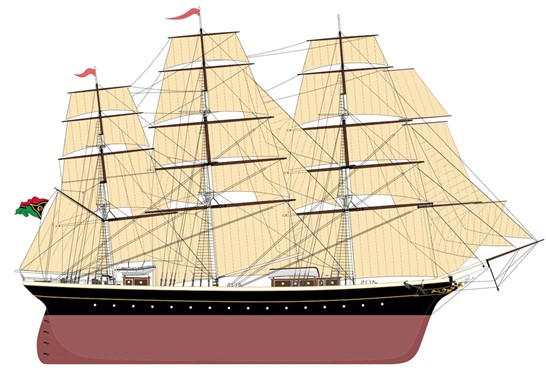

The Brigantine “TRES HOMBRES”

The Brigantine “TRES HOMBRES”

ECOClipper is planned to create a modern fleet of Eco-friendly sailing vessels concentrating on cargoes suiting small producers export their products around the world, such as coffee, tea, spices, and barrels of rum etc., It is designed to carry 500 tonnes of cargo.

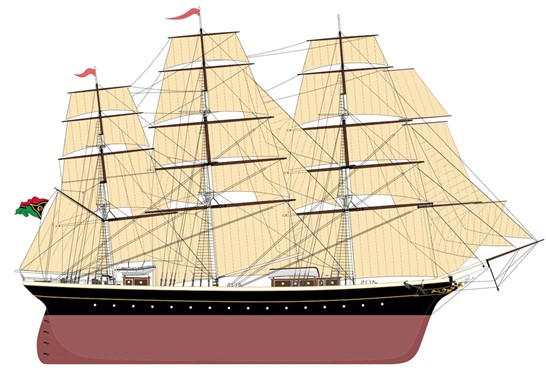

ECOCLIPPER SHIP. The proto type:

The ship will be a steel replica of the Dutch clipper ship, Noach. Originally built in 1857 in Kinderdijk. Noach has been called the fastest Dutch sailing vessel ever! The EcoClipper prototype500 will be the first of a fleet of fast, traditionally built, emission-free cargo packet ships. A packet ship carries cargo and passengers on a regular schedule.

She will sail the deep sea routes: transatlantic, trans-pacific, across Asia (eastern route) and globally. She will have three square-rigged masts, with a total sail area of 976 m2. This state-of-the-art sailing vessel will be an exemplar of ultimate sustainability and seaworthiness.

“ECOCLIPPER”

“ECOCLIPPER”

For more about the ECCOCLIPPER project, see videos and to keep up to date with the project click the link below:

EcoClipper

-oooOooo-

“OCEANBIRD”

Wallenius and Alfa Laval

On a larger scale, two Swedish companies with sustainability on top of the agenda, will join forces: With the goal to achieve truly sustainable shipping.

“Combining our strengths, we will be able to radically reduce the marine industry’s carbon footprint and overall emissions – We are pushing forward to find solutions for a sustainable way to pass freight over the oceans – We want to be part of a solution and inspire others to do the same. It’s the beginning of a new era, for us and global transportation.”

“OCEANBIRD”

Across the Atlantic in under two weeks

The 200 metre long and 40 meters wide cargo vessel will be able to cross the Atlantic in 12 days. The wing sails are all of 80 metres tall, giving the ship a height above water line of appr. 105 metres, but thanks to a telescopic construction they can be lowered, resulting in a vessel height above water line of appr. 45 metres.

7,000 cars can be carried in the cargo hold

90% lower emissions than a vessel with a diesel engine

5 rigs with 80 metres tall wing sails for forward propulsion

12 days to cross the Atlantic with the wind as energy source

To watch a video of this project and to catch up with news please click the link below:

Oceanbird (theoceanbird.com)

Finally, a new development from the famous tyre manufacturing company Michelin.

THE WISAMO PROJECT, AN INNOVATIVE SOLUTION TO HELP DECARBONIZE MARITIME SHIPPING.

The Wing Sail Mobility (WISAMO) project is an automated, telescopic, inflatable wing sail system that can be fitted on both merchant ships and pleasure craft. The system is the product of a collaborative venture between Michelin Research & Development and two Swiss inventors who share the Group’s “all-sustainable” vision.

The inflatable wing sail harnesses the wind, a free, universal and inexhaustible source of propulsion. Its revolutionary design enables a ship to reduce its fuel consumption and thereby have a positive impact on the environment by lowering CO2 emissions.

Designed and developed by the WISAMO project team, the system is installable on most merchant ships and pleasure craft. Especially suitable for ro-ro ships, bulk carriers and oil and gas tankers, it can be fitted as original equipment on newbuilds or retrofitted on in-service vessels.

The wing’s range of use is one of the market’s broadest, with proven effectiveness on many points of sail, and especially when close-hauled (windward). It can be used on every maritime shipping route. The telescopic mast is retractable, making it easy for a ship to enter harbors and pass under bridges. In all, the system can improve a ship’s fuel efficiency by up to 20%*.

A collaboration with Michel Desjoyaux, a world-renowned skipper and ambassador of the project, enables Michelin’s research teams to perfect its development. His input and technical knowledge of this seasoned sailor will enable it to be tested in actual maritime shipping conditions. As Desjoyeaux points out, “the advantage of wind propulsion is that wind energy is clean, free, universal and totally non-controversial. It offers a very promising avenue to improving the environmental impact of merchant ships.”

The WISAMO system will first be fitted on a merchant ship in 2022, when Michelin expects it to go into production following completion of the trial phase.

The WISAMO project is Michelin’s contribution to enabling greener, softer maritime mobility in advance of future regulations. Michelin is also taking action to reduce the environmental impact of its supply chain. In addition to this commitment, and in line with its strategic plan, the Group is basing a portion of its growth on the development of new businesses.

—————————————-

The Brigantine “TRES HOMBRES”

The Brigantine “TRES HOMBRES” “ECOCLIPPER”

“ECOCLIPPER”