Meetings 2024

Here is a list of meeting so far arranged for 2024:

January 11th ‘A Doctor at Sea’ TASC Member Dr Chris Hargreaves

February 8th “Making of the Atom Bomb” Malcolm Byrne

March 14th “The Development of Sunderland Harbour” Stuart Miller

April 11th (Subject to be confirmed) Bernard Hope This will be followed by a short General Meeting.

May 9th “Graf Spee” John Gibson

June 13th (Subject to be confirmed ) Derek Potter

July 11th (To Be Arranged)

August 8th (To Be Arranged)

October 10th (To Be Arranged)

November 14 (To Be Arranged)

Meetings

Our first meeting back was held on the 9th March 2023. This was successful with 25 members attending. Many thanks to our treasurer Phil Work, who gave a most interesting talk with a super collection of slides of Clyde Steamers. The next meeting will be our AGM, on the 13th April 2023 at 2 pm, we hope to have as many members as possible to get the club back on track. Our Member Tom Purvis will also be giving a talk entitled Life of Wellington with Tom’s usual twist!.

We are looking for Speakers, so if you have any ideas please put them forward.

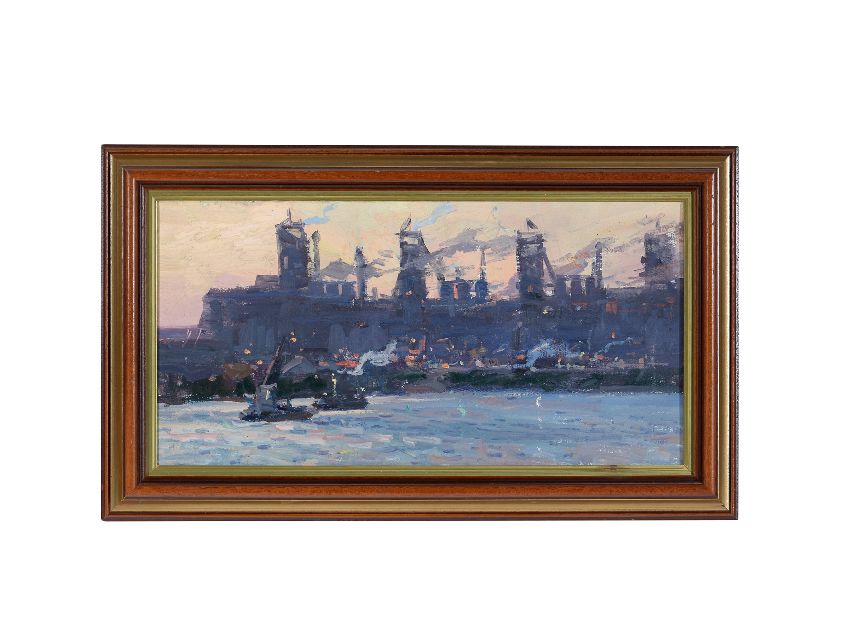

Rare Painting of former Azovstal Steel Works in Mariupol, Ukraine, up for Auction

TASC Member Robert Hunter has kindly shared this topical story with us.

Until May this year, Azovstal Steel Works was a name not known to many, but when it became the epicentre of a horrifying battle in the Russia – Ukrainian War, receiving 38 airstrikes in just one day, causing hundreds of innocent civilian casualties, the heroic defence captured the sympathy and admiration of our nation.

I was among the viewers who watched with horror at what was unfolding on the TV. It was then that I realised that the industrial landscape being destroyed seemed very familiar to me and was in fact the subject of a painting hanging on the wall of my home.

“I found the picture in a junk shop in St Petersburg when I was based there in 1994 and bought it for about US $100 as I thought it was quite dramatic. It’s been on my wall ever since, always with a question mark as to where it was. When I bought it, all they could tell me was that they thought it might be in the Ukraine somewhere.” Said the vendor.

“For thirty years I have wondered about the location, that is until two months ago, when Russia invaded the Ukraine and started to obliterate the Azovstal steelworks at Mariupol, making headline news here for weeks! Every time I see the picture on my wall I think of the horror of what the Russians are doing, and it really effects me”

“Two days ago, I had a visit from John Anderson of Anderson & Garland Auctioneers, a friend of 40 years. I showed him the picture and we decided we would sell it and donate all the proceeds to a suitable Ukrainian charity – With Ukraine.”

“I am delighted, that my 1994 speculative purchase will make a very small but vital contribution to benefit the oppressed Ukrainian people.”

Art Expert John Anderson said “This painting is perhaps one of the only remaining depictions of the Azovstal steel works in The Ukraine, as it stood before. It may be unique. Not only is it is superbly painted, but the work holds great historical significance too.”

The impressionist painting, by Ukrainian Artist Chernyakhovski Georgi Georgievich, will go up for Auction on Thursday 21st July as part of the Anderson & Garland Summer Country House & Fine Interiors Auction and has a Auction Estimate of £500- £800.

(The Auction was very successful and managed to reach a magnificent total of near to £1700.00)

Complexity in ship design can make it tricky for model makers!

Thanks to TASC Member Robert Hunter for sharing the following.

In the 1950s and 60s Bartram’s, Shipbuilders on the river Wear in Sunderland, built a series of 12 or more reefers for Blue Star Line and New Zealand Shipping Company. They were regarded as quite complex vessels at that time and as a young naval architect I was very much involved in their design, their construction, and their commissioning.

Early 1960s we were awarded a contract to build three sister ships for NZSC with the names “Taupo” “Tekoa” and “Tongariro” named after locations in New Zealand and I was appointed Construction Manager on “Taupo” Not easy ships to build to a high specification and additionally Hallen Swinging Derricks for cargo handling were specified requiring very complex and difficult to build mast structures involving massive “D” frames to increase the purchase on the derrick swinging arrangement.

These structures, nine on each vessel were extremely difficult to fabricate and install and caused a deal of heart ache until we were able to master the various techniques required to fabricate and install them and commission the cargo handling equipment,

The length of wire rigging required for each derrick was enormous and compounded the difficulty we experienced. However eventuality we commissioned and delivered all three vessels successfully before, in contrast we embarked on a long term project building a series production of the standard “SD 14”

Fast forward more than 50 years to my retirement in 2008 I had built one or two scratch built ship models, including one of Glenroy my grandfather’s ship which I was rather proud of so decided to try to build a model of “Taupo” the lead ship of the three NZSC reefers.

With some difficulty I was able to put together a mix of photographs and small scale general arrangements and commenced work knowing that I would be hard pressed to make a good enough job and it would take the best part of 12 months or more.

It took longer as I had a six month “holiday” when I lost interest but thankfully that passed and I was able to complete the model, but not without having nearly as much trouble with the “D” frame masts and the miles of rigging on a scale of 1/192 as Bartram’s had experienced full size 50 years previously.

In its glass case in my study it brings back fond memories of myself as a young man striving to build these rather unusual looking vessels which unsurprisingly attracted a lot of attention at the time

The Carbon Footprint of Shipping

We currently have COP26 in progress:

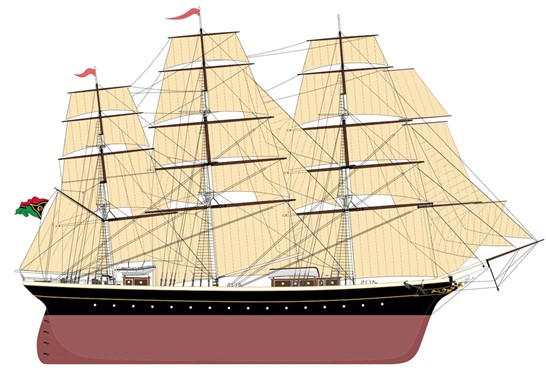

It is interesting to see activity in the world of shipping seeking ways in which to reduce its contribution to greenhouse gasses. One significant area of interest is the harnessing of wind. This is not surprising, when we consider not too many years ago wind propulsion of ships was the norm. A company I worked with for over twenty years Andrew Weir & Co. Ltd., started its impressive shipping business with the purchase in December 1885 of a second-hand sailing ship the “Willowbank”, it went on to expand its sailing ship fleet to become the largest fleet sailing under the Red Ensign. Of course, Andrew Weir subsequently replaced these with modern steamships and then these, with a modern fleet of motor ships. An excellent book telling the story of Andrew Weir and his company is the book written by a friend and former colleague Captain Alistair Macnab under the title “The Shipping Wizard of Kirkcaldy –Andrew Weir’s Bank Line”. A good read. However, getting back to sail; a number of companies are presently engaged in the design and building of cargo ships using the power of the wind, of course, they will utilize modern materials and up-to-the minute technology.

Jorne Langelaan, who lives in Holland, is a modern day sailor Founder & CEO EcoClipper – Co-founder Fairtransport. He and two of his friends the “Tres Hombres” started the company and named their first Brigantine aptly “Tres Hombres”

ECOClipper is planned to create a modern fleet of Eco-friendly sailing vessels concentrating on cargoes suiting small producers export their products around the world, such as coffee, tea, spices, and barrels of rum etc., It is designed to carry 500 tonnes of cargo.

ECOCLIPPER SHIP. The proto type:

The ship will be a steel replica of the Dutch clipper ship, Noach. Originally built in 1857 in Kinderdijk. Noach has been called the fastest Dutch sailing vessel ever! The EcoClipper prototype500 will be the first of a fleet of fast, traditionally built, emission-free cargo packet ships. A packet ship carries cargo and passengers on a regular schedule.

She will sail the deep sea routes: transatlantic, trans-pacific, across Asia (eastern route) and globally. She will have three square-rigged masts, with a total sail area of 976 m2. This state-of-the-art sailing vessel will be an exemplar of ultimate sustainability and seaworthiness.

For more about the ECCOCLIPPER project, see videos and to keep up to date with the project click the link below:

-oooOooo-

“OCEANBIRD”

Wallenius and Alfa Laval

On a larger scale, two Swedish companies with sustainability on top of the agenda, will join forces: With the goal to achieve truly sustainable shipping.

“Combining our strengths, we will be able to radically reduce the marine industry’s carbon footprint and overall emissions – We are pushing forward to find solutions for a sustainable way to pass freight over the oceans – We want to be part of a solution and inspire others to do the same. It’s the beginning of a new era, for us and global transportation.”

“OCEANBIRD”

Across the Atlantic in under two weeks

The 200 metre long and 40 meters wide cargo vessel will be able to cross the Atlantic in 12 days. The wing sails are all of 80 metres tall, giving the ship a height above water line of appr. 105 metres, but thanks to a telescopic construction they can be lowered, resulting in a vessel height above water line of appr. 45 metres.

7,000 cars can be carried in the cargo hold

90% lower emissions than a vessel with a diesel engine

5 rigs with 80 metres tall wing sails for forward propulsion

12 days to cross the Atlantic with the wind as energy source

To watch a video of this project and to catch up with news please click the link below:

Finally, a new development from the famous tyre manufacturing company Michelin.

THE WISAMO PROJECT, AN INNOVATIVE SOLUTION TO HELP DECARBONIZE MARITIME SHIPPING.

The Wing Sail Mobility (WISAMO) project is an automated, telescopic, inflatable wing sail system that can be fitted on both merchant ships and pleasure craft. The system is the product of a collaborative venture between Michelin Research & Development and two Swiss inventors who share the Group’s “all-sustainable” vision.

The inflatable wing sail harnesses the wind, a free, universal and inexhaustible source of propulsion. Its revolutionary design enables a ship to reduce its fuel consumption and thereby have a positive impact on the environment by lowering CO2 emissions.

Designed and developed by the WISAMO project team, the system is installable on most merchant ships and pleasure craft. Especially suitable for ro-ro ships, bulk carriers and oil and gas tankers, it can be fitted as original equipment on newbuilds or retrofitted on in-service vessels.

The wing’s range of use is one of the market’s broadest, with proven effectiveness on many points of sail, and especially when close-hauled (windward). It can be used on every maritime shipping route. The telescopic mast is retractable, making it easy for a ship to enter harbors and pass under bridges. In all, the system can improve a ship’s fuel efficiency by up to 20%*.

A collaboration with Michel Desjoyaux, a world-renowned skipper and ambassador of the project, enables Michelin’s research teams to perfect its development. His input and technical knowledge of this seasoned sailor will enable it to be tested in actual maritime shipping conditions. As Desjoyeaux points out, “the advantage of wind propulsion is that wind energy is clean, free, universal and totally non-controversial. It offers a very promising avenue to improving the environmental impact of merchant ships.”

The WISAMO system will first be fitted on a merchant ship in 2022, when Michelin expects it to go into production following completion of the trial phase.

The WISAMO project is Michelin’s contribution to enabling greener, softer maritime mobility in advance of future regulations. Michelin is also taking action to reduce the environmental impact of its supply chain. In addition to this commitment, and in line with its strategic plan, the Group is basing a portion of its growth on the development of new businesses.

—————————————-

End of an Era

End of an Era

2021 Marks the end of an era with the very last shipment of coal leaving the Port of Tyne.

Coal was from medieval times the lifeblood of industry and a key part of life in the North East. After the 1980s miners’ strike, 156 collieries closed nationwide, some merged… only to be axed as ‘uneconomic’. The last North East deep mine closed in 2005.

Coal was King and it fuelled industries like steel and heavy engineering, railways and domestic heating. At its peak in 1913, the Great North Coalfield employed almost 250,000 men, producing over 56 million tons of coal every year from about 400 pits. The North East produced 25% of Britain’s coal in 1913, and the nation was heavily dependent on ‘black gold’

The term ‘carrying coals to Newcastle’ could have been invented specifically for the Port of Tyne, as it handled the majority of coal exports from the local mines in the late nineteenth and early twentieth centuries. In the sixty years from 1952 to 2012,

The Port has changed and diversified, handling all manner of goods for import and export, along with modern passenger facilities, to become a thriving business serving the North East.

It is an exciting time in the Port of Tyne today, with so much going on, It is building new business partnerships and has recently launched the Tyne Clean Energy Park, boosting the North East’s renewables infrastructure. The Region’s ‘most versatile’ clean energy park, Tyne Clean Energy Park provides a unique co-location for the renewables sector with unrestricted, 24/7 marine access.

Offshore: The Port is ‘offshore wind ready’ and is the site of the operations and maintenance base for the biggest wind farm in the world, Dogger Bank. The Tyne also houses an extensive offshore supply base and has partnerships with a number of colleges and universities in the region.

Automotive: The Port is the UK’s second largest car exporter with customers including Nissan and VW. It has a solid reputation in the automotive world. It handles around 600,000 cars a year, as well as vans, trucks, mining, and construction equipment and even train carriages.

Dry Bulk Cargoes:

Aggregates, agribulks, chemicals, coal, scrap metal…“Cranes, grabs, hoppers, loading shovels, weighers, conveyor belts, rail links…etc., The Port handles millions of tonnes of bulk cargoes every year. It is also been recognised as an industry pioneer and leader in handling the relatively new cargo of wood pellet.”

LIQUID BULK: Liquid bulks are handled at the Port of Tyne by Exolum Terminals Ltd, one of the largest independent bulk liquid storage providers in Northern Europe. “We work closely with Exolum to provide all of the practical, marine and safety support the company needs”.“Exolum has 62 tanks at its Tyne Terminal, ranging in capacity from 56m2 to 6,000m2. There are specialist tank types to meet the particular needs of different contracts and customers.

Containers: The Port has a dedicated container terminal capable of handling 100,000 TEU per annum with regular European feeder services.

The Port has long term contracts with major tea giants and handles thousands of tonnes of tea per year. The Port also works very closely with the famous (local) International clothes firm Barbour, and the heavy machinery manufacturer Komatsu this demonstrates the diversity and range of cargoes handled by the Port.

In way of contrast and for interest take a look at the Port of Tyne back in the year 1965, link suggested by Phil Work TASC Member (Treasurer) We are grateful to Yorkshire Film Archive for permission to link this film.)

A message from your Chairman

As we progress our passage through these unchartered times. I hope that all our Members, Guests and their families are managing to stay safe and well. Let us hope that it will not be too long before we can resume our normal lives. Here are a couple of good news stories to brighten our day!

Port of Tyne to host Dogger Bank operations hub

Port of Tyne to host Dogger Bank operations hub

Port of Tyne to host Dogger Bank operations hub

Equinor and SSE Renewables have chosen the Port of Tyne in north east England as the site for the operations and maintenance (O&M) hub serving the 3600MW Dogger Bank offshore wind farm.

Equinor is constructing the facility. The joint venture partner will operate the wind farm for its expected lifetime of more than 25 years and will base its O&M teams at the centre.

The multi-million pound site will includes both office space and a warehouse.

Dogger bank is being built in three 1.2GW phases, with the first expected to starting producing electricity in 2023.

The project is expected to generate over 200 direct jobs in the region, as well as opportunities for companies at all levels of the supply chain.

Dogger Bank will require a total capital investment of approximately £9bn between 2020 and 2026.

Construction of the wind farm, led by SSE Renewables, began in January 2020.

Secretary of State for Business Alok Sharma said: “This new facility is fantastic news for Tyneside and the North East of England. Renewable energy is one of the UK’s great success stories, providing over a third of our electricity and thousands of jobs.

“Projects like Dogger Bank will be a key part of ensuring a green and resilient economic recovery as well as reaching our target of net zero emissions by 2050.”

Equinor North Sea new energy solutions senior vice president Stephen Bull said: “The UK government has legislated to cut carbon emissions to net zero by 2050.

“Major scale renewable energy projects like Dogger Bank ensures Britain’s leadership as the #1 offshore wind nation. Moreover, the project brings new investment to the UK, at a challenging time for us all, and secures over 200 jobs in the region as well as new opportunities in a future-fit growth sector.

“The North East has a strong industrial heritage and a supply area that stretches north and south of the River Tyne. With a strong low-carbon vision for the future; as well as targets to become net zero in its own operations by 2030 the Port of Tyne is clearly well set up to attract future investments which we hope will complement our activities.

“We are extremely proud that our skilled teams will operate the world’s largest offshore wind farm from here and look forward to becoming part of the community, and strengthening our low-carbon commitment to the North East.”

SSE Renewables director of capital projects Paul Cooley said: “The announcement today cements SSE Renewables’ and Equinor’s commitment to developing long term jobs and economic benefit in the UK and we are very pleased to welcome the Port of Tyne to the project.

“The O&M base will bring significant socio-economic benefits to the local area during construction and throughout the projects lifetime, as we have seen on our previous offshore wind projects including Beatrice.

“Dogger Bank will help drive the transition to a net zero future and we are continuing our work to construct the largest offshore wind farm in the world safely.”

The Port of Tyne recently launched its ‘Tyne 2050’ plan with a vision to become one of the most environmentally sustainable ports in the UK by 2030.

Offshore wind is a “key component” of the strategy.

The main recruitment activity for the O&M facility will begin in early 2022 and ramp up as the project nears operation, with the first phase due to begin producing electricity in 2023.

RenewableUK deputy chief executive Melanie Onn said: “This is a great example of how our member companies in the offshore wind sector are investing billions of pounds in developing vital new energy infrastructure all around the UK.

“Offshore wind is creating new opportunities and employment in port towns and coastal communities throughout the country.

“As we look to the future, renewables offer us a way to rebuild our economy after the coronavirus pandemic, not just by developing projects here but by exporting our valuable expertise around the world. We can consolidate our global lead in offshore wind and in developing innovative technologies like floating wind, marine power and renewable hydrogen, as well as restarting the development of new onshore wind projects.”

reNEWS BIZ

Formica Group moves Import operations North to Port of Tyne

Image Port of Tyne

Leading laminate surface manufacturer Formica Group has signed a new deal with Port of Tyne to move its UK import operations to South Shields bringing around 500 containers a year into the Port.

Formica Group, based in North Shields & Newton Aycliffe, supplies branded surfaces for worldwide commercial and residential markets and imports paper reels from Savannah in the US.

The paper reels will be shipped from Savannah to either Felixstowe or Rotterdam before being transferred to South Shields on coastal feeder vessels and then moved into the Port of Tyne’s deep-water container facility.

The containers will then be unloaded into a port centric warehouse, which will store about 2,500 tonnes of paper before being called off for delivery on a Port of Tyne vehicle to Formica’s North Shields production site.

Port of Tyne’s Commercial Director Richard Newton, said: “Our close proximity to Formica’s production site in North Shields will improve turnaround times, increase efficiency and use considerably fewer road miles, saving time, carbon and money.

“Our award winning customer service, which achieved 93% satisfaction rate, was critical in winning this business; we are in constant dialogue with our customers and form strong partnerships. Combined with our port centric approach, which forms an integral part of our customers’ supply chain, it gives customers one less thing to worry about. We are delighted to secure this deal and look forward to working with Formica.”

Dan Baker, European Category Manager at Formica Group, said: “Sustainability was a crucial factor in choosing to work with the Port of Tyne, which has allowed us to save about 40,000 road miles per year. Environmental sustainability is increasingly important for Formica’s supply chain.”

Formica Group’s Coast Road Factory in North Shields, which recently underwent a multimillion-pound renovation, employs more than 400 people and serves as the company’s European headquarters.

This news comes after the Port of Tyne recently expanded capacity at its container terminal by 40% to handle a throughput of around 100,000 TEUs per year (Twenty Feet Equivalent Units).

Port of Tyne also gained Authorised Economic Operator (AEO) status, an internationally recognised quality mark, simplifying customs processes and certifying that its role in the international supply chain is secure.

Sea News, May 13

The Brigantine “TRES HOMBRES”

The Brigantine “TRES HOMBRES” “ECOCLIPPER”

“ECOCLIPPER”